Special Features

- Tension meter DNW can be used only for pretensioned, non-moving ropes

- Calibration is done using a closed force system

- Due to the material path the max. error is approx. 3 % FS (full scale)

- Special lever reduces the force to extend outer rollers to capture the material to be measured

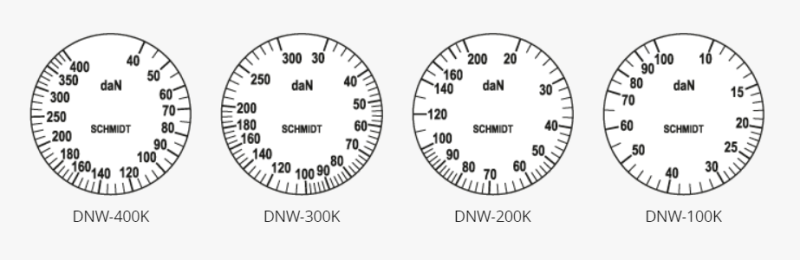

- Tension meter with large, easy to read scale (54 mm Ø)

- Linearized scale provides a better reading

- Tension meter with shock-resistant movement

- Special guides on the bracket assembly and roller shifting mechanism ensure easy acquisition of the material

Standard Features

- Everything in operator’s view:

– the guide rollers

– the measured material

– the readings - Ball-bearing mounted, V-grooved guide rollers

- Each instrument is individually calibrated for highest accuracy

- Special calibration is available

- Tension Meter with rugged aluminium housing

- Certificate of Compliance with the order 2.1 according EN 10204 is included

- Optionally available: Inspection Certificate 3.1 according EN 10204 with calibration report

Available Models

| Model | Measuring Range |

Measuring Head Width* |

SCHMIDT Calibration Material** |

| DNW-100K | 10 – 100 daN | 265 mm | steel rope 2 mm Ø |

| DNW-200K | 20 – 200 daN | 265 mm | steel rope 2 mm Ø |

| DNW-300K | 30 – 300 daN | 265 mm | steel rope 3 mm Ø |

| DNW-400K | 40 – 400 daN | 265 mm | steel rope 4 mm Ø |

* Outer distance between outside guide rollers

** SCHMIDT calibration material twisted steel rope

Calibration to customized material:

If process material differs significantly from the SCHMIDT calibration material in diameter, rigidity or shape, special calibration using customer supplied samples is recommended. For this purpose a material sample of about 5 m should be supplied.

Tension meter DNW with carrying case, operating instruction in German or English (as requested), Certificate of Compliance with the order 2.1 according EN 10204 free of charge

Tension meter DNW with carrying case, operating instruction in German or English (as requested), Certificate of Compliance with the order 2.1 according EN 10204 free of charge