Special Features

- Tension sensor FS1 with integrated measuring amplifier and high accuracy of 1.5 % FS

- Different guide rollers are available according to the application

- Various output signals are available:

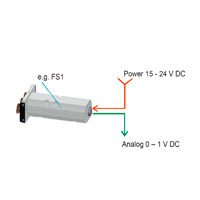

– analog: 0 – 1 V DC (standard), 0 – 10 V DC (optional)

– digital (optional): USB, RS-232, Wi-Fi, RS-422 – see model FS1-422 (FS1-100 and higher)

– current: 4 – 20 mA (optional) - Easy installation, even afterwards, on existing machines

- 2 Mounting possibilities: housing mounting or cylindrical hole mounting (mounting cut out 38.5 – 40 mm Ø)

The housing of sensors with digital output are larger and need as mounting cut a long hole R 19 with a length of 54 mm - Easy calibration to customized material by operator – zero and gain calibration is required

- Measuring principle – load cell with high quality strain gauge bridge

- Tension sensor with mechanical overload protection

Note: a wide range of custom designed models as well modifications are available on request. Please contact us with your demand!

Standard Features

- V-grooved guide rollers, ball-bearing mounted

- Tension sensor FS1 with Aluminium housing

- Required power supply +15…24 V DC (regulated)

- Certificate of Compliance with the order 2.1 according EN 10204 is included

- Optionally available: Inspection Certificate 3.1 according EN 10204 with calibration report

Available Models

| Model | Tension Range |

Measuring Head Width* |

SCHMIDT Calibration Material** |

| FS1-50 | 0 – 50 cN | 64 mm | PA: 0.12 mm Ø |

| FS1-100 | 0 – 100 cN | 64 mm | PA: 0.12 mm Ø |

| FS1-200 | 0 – 200 cN | 64 mm | PA: 0.12 mm Ø |

| FS1-500 | 0 – 500 cN | 64 mm | PA: 0.20 mm Ø |

| FS1-1000 | 0 – 1000 cN | 64 mm | PA: 0.30 mm Ø |

| FS1-2000 | 0 – 2000 cN | 124 mm | PA: 0.50 mm Ø |

| FS1-5000 | 0 – 5000 cN | 124 mm | PA: 0.80 mm Ø |

| FS1-10K | 0 – 10 daN | 124 mm | PA: 1.00 mm Ø |

| FS1-20K | 0 – 20 daN | 224 mm | PA: 1.50 mm Ø |

| FS1-50K | 0 – 50 daN | 224 mm | steel rope 1.50 mm Ø |

Other tension ranges and measuring head widths available on request.

Other measuring units available, such as g or kg.

* Outer dimensions of front plate

** Suitable for 95 % of applications PA = Polyamide Monofilament

Calibration to customized material:

If process material differs significantly from the SCHMIDT calibration material in diameter, rigidity or shape, special calibration using customer supplied samples is recommended. For this purpose a material sample of about 5 m should be supplied.

Cable for USB output to connect the tension meter to a PC.

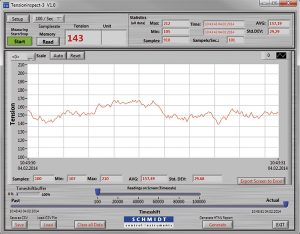

Cable for USB output to connect the tension meter to a PC. For displaying and saving readings on a PC (Win 7 and higher; 32 bit and 64 bit).

For displaying and saving readings on a PC (Win 7 and higher; 32 bit and 64 bit). Connector suitable for sensors of FS series,

Connector suitable for sensors of FS series, Plug suitable for sensors of FS series,

Plug suitable for sensors of FS series, Connecting cable for an analog output.

Connecting cable for an analog output. Connecting cable for an analog output.

Connecting cable for an analog output. Connecting cable for analog output.

Connecting cable for analog output. Connecting cable for tension sensor FS1 with RS-232 interface – Code 232:

Connecting cable for tension sensor FS1 with RS-232 interface – Code 232: Extension cable for RS-232 connecting cable EK0640, length 2 m

Extension cable for RS-232 connecting cable EK0640, length 2 m Adapter from RS-232 to USB.

Adapter from RS-232 to USB. Output signal: 0 – 1 V DC

Output signal: 0 – 1 V DC