The Positest AT-A Automatic Adhesion Tester measures the force required to pull a specified test area of coating away from a substrate using hydraulic pressure. An electronically controlled hydraulic pump automatically applies smooth and continuous pull-off pressure. The pump greatly reduces user effort and the risk of influencing the pulling process.

The AT-A’s built-in rechargeable battery performs over 200 tests per charge. The supplied AC adapter / charger allows you to continue testing with AC power while the battery recharges.

The AT-A is features an environmentally sealed enclosure. It is weatherproof, dustproof and shockproof. Meeting or exceeding IP65 rating.

Model Comparison

| Order Code | ATA20 | ATA50 | ATA50T | ATA50C |

|---|---|---|---|---|

| Dolly size and stand-off* | 20 mm | 50 mm | 50 mm² | 50 mm |

| Typical Applications | Higher bond strength coating on metal | Lower bond strength coatings on wood, concrete and plastic | BS EN 12004-2 Cementitious adhesives for tiles |

ASTM C1583 Concrete surfaces and overlays |

| Range | 0.7 – 24 MPa 100 – 3500 psi 100 – 7550 N |

0.4 – 3.8 MPa 50 – 560 psi 100 – 7550 N |

0.4 – 3.033 MPa 50 – 440 psi 100 – 7550 N |

0.4 – 3.8 MPa 50 – 560 psi 100 – 7550 N |

| Resolution | 0.01 MPa (1 psi) | |||

| Accuracy | ± 1% Full Scale | |||

| Included Dollies | ⌀20 mm (qty 20) Aluminum | ⌀50 mm (qty 8) Aluminum | 50 mm² Plate (qty 4) with threaded post Steel | ⌀50 mm (qty 4) with ≥ 25 mm thickness Steel |

| Cutting Tool | 20 mm hole saw | 50 mm hole saw | – | 50 mm diamond grit hole saw with arbor |

* Optional 20mm/50mm/50 mm C1583/50 mm Tile Conversion Kits allow each model to be used with alternative dolly sizes. Custom 10 and 14 mm dollies are available for special applications (compatible with 20 mm stand off).

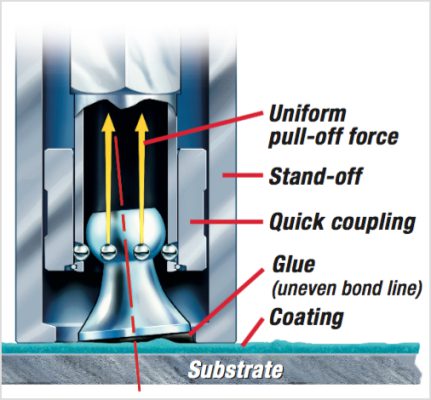

ATA Self-Alignment Feature

Unequal pulling force during testing caused by uneven adhesive bond lines and coating surfaces can result in random, unexplainable readings. To obtain more repeatable and meaningful adhesion measurements, it is imperative that the pulling force applied to the test dolly is uniformly distributed over the surface being tested.

Unequal pulling force during testing caused by uneven adhesive bond lines and coating surfaces can result in random, unexplainable readings. To obtain more repeatable and meaningful adhesion measurements, it is imperative that the pulling force applied to the test dolly is uniformly distributed over the surface being tested.

Both the PosiTest AT-M manual and PosiTest AT-A automatic models compensate for misalignment. The self-aligning, quick-coupling actuator and spherical articulating dolly head enable uniform distribution of the pulling force over the surface being tested, preventing a one-sided pull-off.

Memory and Reporting Features

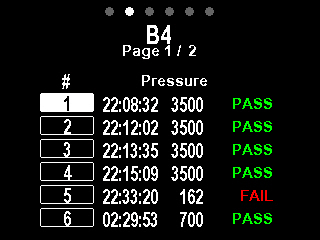

- Internal memory stores maximum pull-off pressure, rate of pull, test duration and dolly size for 100,000 pulls in up to 1,000 batches

- Record the results as pass/fail and the nature of fracture – cohesive, adhesive and glue failures

- Wirelessly connect to your smart device using our free PosiTector App (Apple iOS and Android)

- WiFi technology wirelessly communicates with PosiSoft.net, downloads software updates and allows access to stored measurement data using standard web browsers

- PosiSoft USB Drive – stored readings and graphs can be accessed via USB using universal PC/Mac web browsers or file explorers. No software required

- Compatible wit PosiSoft Desktop, PosiSoft.net and PosiTector App (Apple iOS and Android) software solutions

PosiTector App Features

- Add images and notes using the camera or keyboard

- Create customized, professional PDF reports

- Share, backup, synchronize and report measurement data

- Auto-pairing Bluetooth (BLE) connection

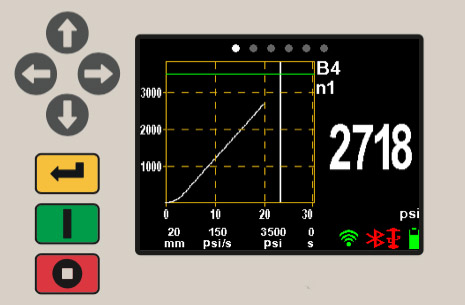

Touch Screen Display

Use the touch screen to interact with menu options. Swipe horizontally to navigate between views or vertically to move between batch readings. Alternatively, the keypad can be used for navigation and selection.

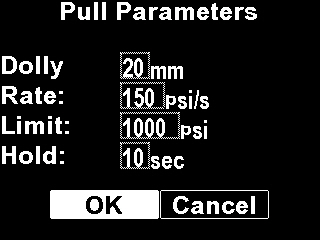

User adjustable dolly size, pull rate, pull limit and hold time.

Batch summary provides an at-a-glance review of test results.

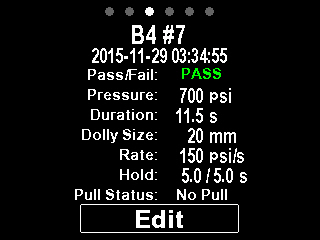

View test parameters and reading results. Reading is recorded as pass or fail based on set test parameters. The pass/fail results can be revised.

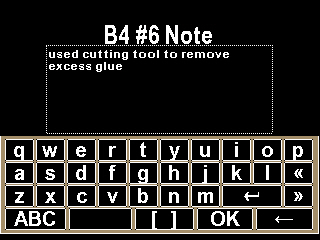

Notes can be added for each reading.

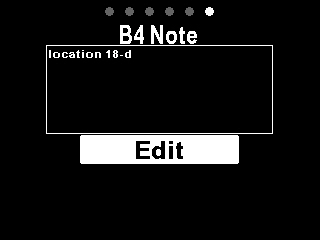

Include a note for a batch (group) of readings.

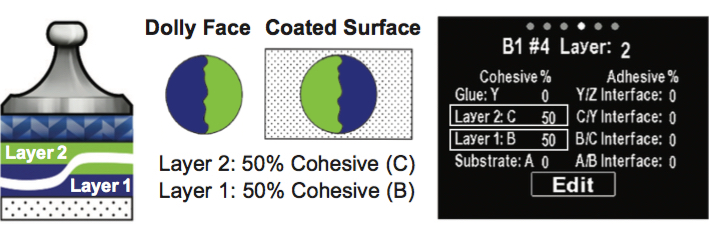

Record the nature of failure – cohesive, adhesive and glue failures.

Recording the Nature of the Fracture

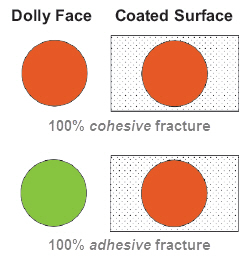

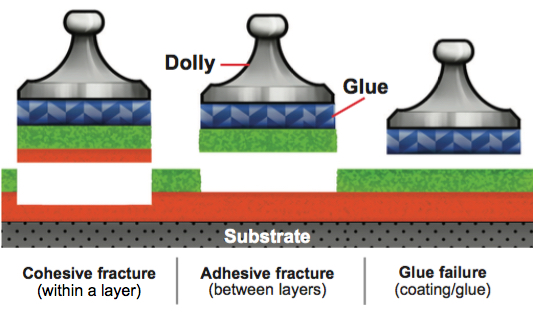

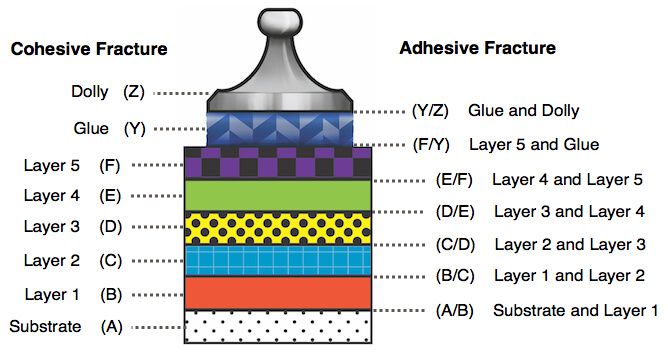

Upon completion of a pull-off test, the dolly and coated surface should be examined. In addition to pull-off force, many National and International standards such as ASTM D4541 and ISO 4624 require the nature of the fracture to be recorded.

- Cohesive fracture: fracture occurs within a coating layer (same coating on dolly face and coated surface).

- Adhesive fracture: fracture occurs at the interface between layers (coating on dolly face differs from surface).

- Glue failure: visible separation of the glue from itself, the coating or dolly (no coating visible on the dolly face).

The cohesive and adhesive fracture visual analysis can be recorded using the PosiTest AT-A’s keypad or touch screen display. Alternatively, the information can be reported using the PosiTector App.

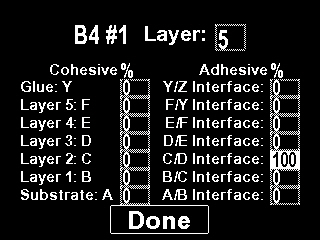

Fractures are visually estimated and recorded as a percent of each. The two layer example below illustrates a cohesive fracture within coating layer 1 and layer 2 (visually estimated at 50% each). Recorded results are included in reports.

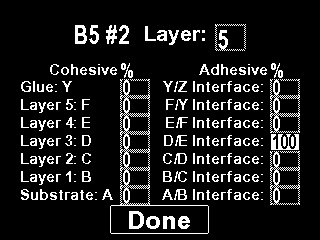

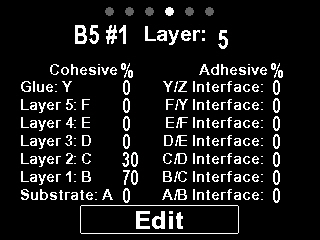

Examples

(based on above five layer illustration)

100% cohesive fracture at D/E coating interface (layer 3/layer 4)

100% cohesive fracture at D/E coating interface (layer 3/layer 4)

70% cohesive failure within layer 1; 30% cohesive within layer 2

70% cohesive failure within layer 1; 30% cohesive within layer 2

Complete Kit

The PosiTest AT kits come complete with Automatic Adhesion Tester, built-in rechargeable NiMH battery with charger, dollies, abrasive pad, cutting tool, glue with mixing sticks and palettes, cotton swabs, USB cable, PosiSoft Software, instruction booklet and video, shoulder strap, Certificate of Calibration traceable to NIST, two-year warranty, and a sturdy, lightweight carrying case.

| Item | Descrıptıon | |||

|---|---|---|---|---|

|

ATA20

|

Positector AT Automatic Adhesion Tester with 20mm Dollies Complete Kit – ATA20A

|

|||

| ATA50 |

Positector AT Automatic Adhesion Tester with 50mm Dollies Complete Kit – ATA50A-B

|

|||

| ATA50C |

Positector AT Automatic Adhesion Tester with 50mm C1583 Kit – ATA50C-B

|

|||

|

ATA50T

|

Positector AT Automatic Adhesion Tester with 50mm2 Tile Kit – ATA50T-B

|

|||

| Accessorıes | ||||

|

CASEATM-P

|

Pelican Case for PosiTest AT Manual Pull-Off Adhesion Testers

|

|||

|

CASEATAB-P

|

Pelican Case for PosiTest AT Automatic Pull-Off Adhesion Testers

|

|||

|

ATADHESIVEKIT

|

Additional Adhesive Kit – AT-ADHESIVE

|

|||

|

TMPLTAS

|

Drilling Template for 50 mm Dollies – AT-TEMP

|

|||

|

AT-Verify

|

Adhesion Tester Accuracy Verification Kit – ATVERIFY

|

|||

| Conversıon Kıts | ||||

|

AT-20-KIT

|

Includes 20 mm stand-off, holesaw and 20 test dollies – AT20KIT

|

|||

| AT50CKIT |

Includes 50 mm stand-off, holesaw and 12 test dollies – AT50KIT

|

|||

|

AT50CKIT

|

50 mm C1583 Conversion Kit – Includes 50 mm C1583 steel dollies (4), 50 mm diamond grit cutting tool with arbor and 50 mm C1583 stand-off

|

|||

|

AT50TKIT

|

50 mm x 50 mm Tile Conversion Kit – Includes 50 mm x 50 mm steel dollies (4), and 50 mm x 50 mm stand-off

|

|||

| Dollıes | ||||

|

DOLLY10

|

10mm Dollies – 10 Pack – AT-10

|

|||

|

DOLLY14

|

14mm Dollies – 10 Pack – AT-14

|

|||

|

DOLLY20

|

20mm Dollies – 10 Pack – AT-20

|

|||

|

DOLLY50

|

50mm Dollies – 4 Pack, Requires Standoff Supplied in AT-50-KIT, old pn AT-50

|

|||

|

DOLLY50C

|

50 mm C1583 Dollies – 2 Pack, Requires Standoff Supplied in AT50CKIT

|

|||

|

DOLLY50T

|

50 mm2 Tile Dollies – 4 Pack, Requires Standoff Supplied in AT50TKIT

|

|||

|

PLATE50T

|

50 mm2 Plate – 4 Pack, Requires Standoff Supplied in AT50TKIT

|

|||

| Dolly Multıpacks | ||||

|

DOLLY10APK100

|

10mm Dollies – 100 Pack

|

|||

|

DOLLY14APK100

|

14mm Dollies – 100 Pack

|

|||

|

DOLLY20APK100

|

20mm Dollies – 100 Pack

|

|||

|

DOLLY50APK50

|

50mm Dollies – 50 Pack, Requires 50mm Standoff Supplied in AT-50A-KIT. Not for use with AT-50C-KIT.

|

|||