Special Features

- Tension meter DTS with large, backlight LCD-display

- 3 different display modes:

– numeric

– numeric with bargraph

– numeric with graph (Time-Tension) - The display rotates in 90° steps for better reading

- New, unique, force reduced material catching system

- Thickness compensation: to reach highest accuracy the diameter of the material to be measured can be set with a wheel and will be displayed in the screen (not available for all models)

- Automatic „Zero-Setting“ in each measuring position using a special sensor technique

- 4 Material memory locations for customer made calibrations

- Calibration adjustment for fine tuning of the calibration if material differs from the used calibration material

- Programmable MIN- and MAX alarms: indication in the display, if reading is out of limits

- High speed data sampling (internal 8 kHz) and recording of MIN-, MAX-, last reading, PEAKS, average and standard deviation

- Selectable units of measurement: cN, daN, g, kg, N, lb

- Menu set-up in English or German language

- Flexible menu set-up to meet operators demand

- Some functions of tension meter DTS can be password protected

Note: Tension meter DTX offers additional features, like interface, statistical evaluation on PC and a large internal memory.

Standard Features

- Everything in operator’s view:

– the guide rollers

– the measured material

– the readings - Filament guide and roller shifting mechanism ensure easy acquisition of the running material

- Ball-bearing mounted, V-grooved guide rollers

- Rubberized handle provides a secure hold in the operators‘ hand

- Tension meter with rugged aluminium housing

- LiPo accumulator (approx. 40 hours continuous operation) with AC adapter

- CE certified, interference resistant against static electrifications

- Certificate of Compliance with the order 2.1 according EN 10204 is included

- Optionally available: Inspection Certificate 3.1 according EN 10204 with calibration report

Available Models

| Model | Measuring Range |

Resolution | Measuring Head Width* |

Applications Textile Industry e. g. Yarn Count |

Applications Wire Industrie e .g. soft-annealed copper wire |

SCHMIDT Calibration Material PA** |

Material Thickness Compensator |

| DTS-200 | 1 – 200.0 cN | 0.1 cN | 66 mm | max. 200 tex | max. 0.15 mm Ø | 0.12 mm Ø | |

| DTS-500 | 1 – 500.0 cN | 0.1 cN | 66 mm | max. 500 tex | 0.05 – 0.25 mm Ø | 0.12 + 0.20 mm Ø | X |

| DTS-1000 | 10 – 1000 cN | 1 cN | 66 mm | max. 1000 tex | 0.10 – 0.40 mm Ø | 0.20 + 0.40 mm Ø | X |

| DTS-2000 | 20 – 2000 cN | 1 cN | 66 mm | max. 2000 tex | 0.30 – 0.60 mm Ø | 0.40 + 0.70 mm Ø | X |

| DTS-2500 | 25 – 2500 cN | 1 cN | 116 mm | max. 2500 tex | 0.30 – 0.70 mm Ø | 0.40 + 0.70 mm Ø | X |

| DTS-4000 | 40 – 4000 cN | 1 cN | 66 mm | max. 4000 tex | 0.35 – 0.90 mm Ø | 0.50 + 0.90 mm Ø | X |

| DTS-5000 | 50 – 5000 cN | 1 cN | 116 mm | max. 5000 tex | 0.40 – 1.00 mm Ø | 0.60 + 1.20 mm Ø | X |

| DTS-10K | 0.1 – 10.00 daN | 0.01 daN | 116 mm | max. 10000 tex | 0.70 – 1.40 mm Ø | 0.80 + 1.40 mm Ø | X |

| DTS-20K | 0.2 – 20.00 daN | 0.01 daN | 166 mm | max. 20000 tex | 1.00 – 2.00 mm Ø | 1.20 + 1.80 mm Ø | X |

| DTS-30K | 0.3 – 30.00 daN | 0.01 daN | 216 mm | max. 30000 tex | 1.20 – 2.50 mm Ø | 1.40 + 2.20 mm Ø | X |

| DTS-50K | 0.5 – 50.00 daN | 0.01 daN | 216 mm | max. 50000 tex | 1.40 – 3.00 mm Ø | steel rope 1.5 mm Ø (7 x 7 x 0.2) |

|

| DTS-60K-V1 | 0.6 – 60.00 daN | 0.01 daN | 280 mm | max. 60000 tex | 1.80 – 3.50 mm Ø | steel rope 2.0 mm Ø (7 x 7 x 0.3) |

* Depending on model, either width of filament guide or outer distance between outside guide rollers

** Suitable for 95 % of applications

USB AC adapter with 4 adapters (EU/USA/UK/AUS-NZ) for 100 – 240 V AC and USB cable for loading the accumulator

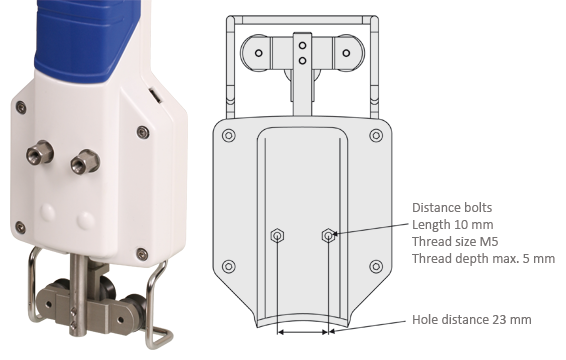

USB AC adapter with 4 adapters (EU/USA/UK/AUS-NZ) for 100 – 240 V AC and USB cable for loading the accumulator To mount the gauge for online use, the housing can be equipped with mounting threads. There are to bolts with M5 female thread on the rear side. This feature cannot be installed afterwords.

To mount the gauge for online use, the housing can be equipped with mounting threads. There are to bolts with M5 female thread on the rear side. This feature cannot be installed afterwords. Tension meter DTS with carrying case, accumulator and AC adapter with 4 adapters (EU/US/UK/AUS-NZ), USB cable, Certificate of compliance with the order 2.1 according EN 10204 free of charge, instruction manual in German or English (as requested)

Tension meter DTS with carrying case, accumulator and AC adapter with 4 adapters (EU/US/UK/AUS-NZ), USB cable, Certificate of compliance with the order 2.1 according EN 10204 free of charge, instruction manual in German or English (as requested)