Special Features

- Tension sensor FSR-422 with integrated microprocessor controlled measuring amplifier and RS-422 interface for multi station system

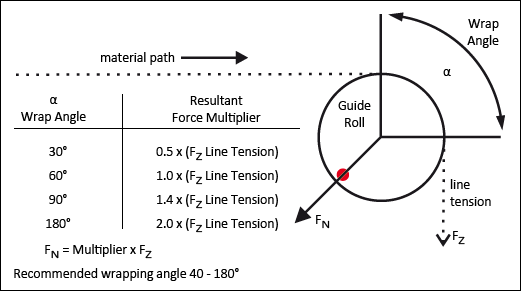

- Sensor for installation at an existing deflection pulley; the in- and outcoming angle β has to be 20° or more.

- Ball-bearing mounted steel or aluminium guide rollers 29.5 mm and 70 mm groove Ø,

– V-grooved (for material with max. 4 mm Ø)

– U-grooved (for material with 3 up to 10 mm Ø)

– tape grooved (for material with max. width of 10 mm) - Easy mounting of customer provided rollers – please contact us!

- Easy installation, even afterwards, on existing machines

- 2 Mounting possibilities: housing mounting or cylindrical hole mounting (mounting cut out: long hole R 19 mm, length 54 mm)

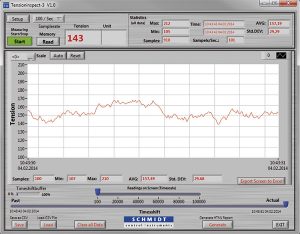

- Easy calibration to customized material by operator – zero and gain calibration is required

- Measuring principle – load cell with high quality strain gauge bridge

- Tension sensor with mechanical overload protection

Standard Features

- Control lamp shows operative mode availability

- Tension sensor FSR-422 with aluminium housing

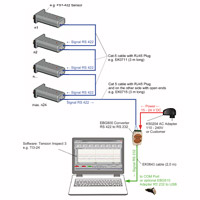

- CAT 5 cables are used for data transfer

- required power supply +15…24 V DC (regulated)

- Certificate of Compliance with the order 2.1 according EN 10204 is included

- Optionally available: Inspection Certificate 3.1 according EN 10204 with calibration report

Special features of the RS-422 interface:

- Up to 24 sensors with different tension ranges and designs may be connected in one line (data transfer max. 200 readings/sec.)

- Connection to RS-232 using a converter (RS-422 – RS-232).

- The RS-422 signal can be used for a single sensor over a distance of 1000 m.

- Each sensor can individually be addressed and set up

- Can be connected to PLC controls with digital input

- Simple connection to BUS-Systems using gateways

Available Models

| Model | Nominal Load |

| FSR-10N-422 | 0 – 10 N |

| FSR-20N-422 | 0 – 20 N |

| FSR-50N-422 | 0 – 50 N |

| FSR-100N-422 | 0 – 100 N |

| FSR-200N-422 | 0 – 200 N |

| FSR-500N-422 | 0 – 500 N |

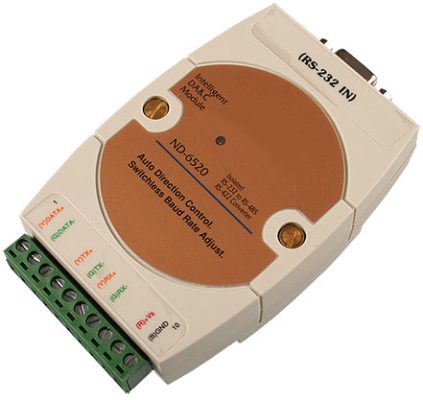

Converter from RS-422 to RS-232 with terminal strip.

Converter from RS-422 to RS-232 with terminal strip.

Cat 5 cable for series connection of FS sensors.

Cat 5 cable for series connection of FS sensors. Connecting cable for connecting EBG-800 converter to PC, length 2 m.

Connecting cable for connecting EBG-800 converter to PC, length 2 m. Recharger with 4 adapters (EU/USA/UK/AUS-NZL) for worldwide use,

Recharger with 4 adapters (EU/USA/UK/AUS-NZL) for worldwide use,