Special Features

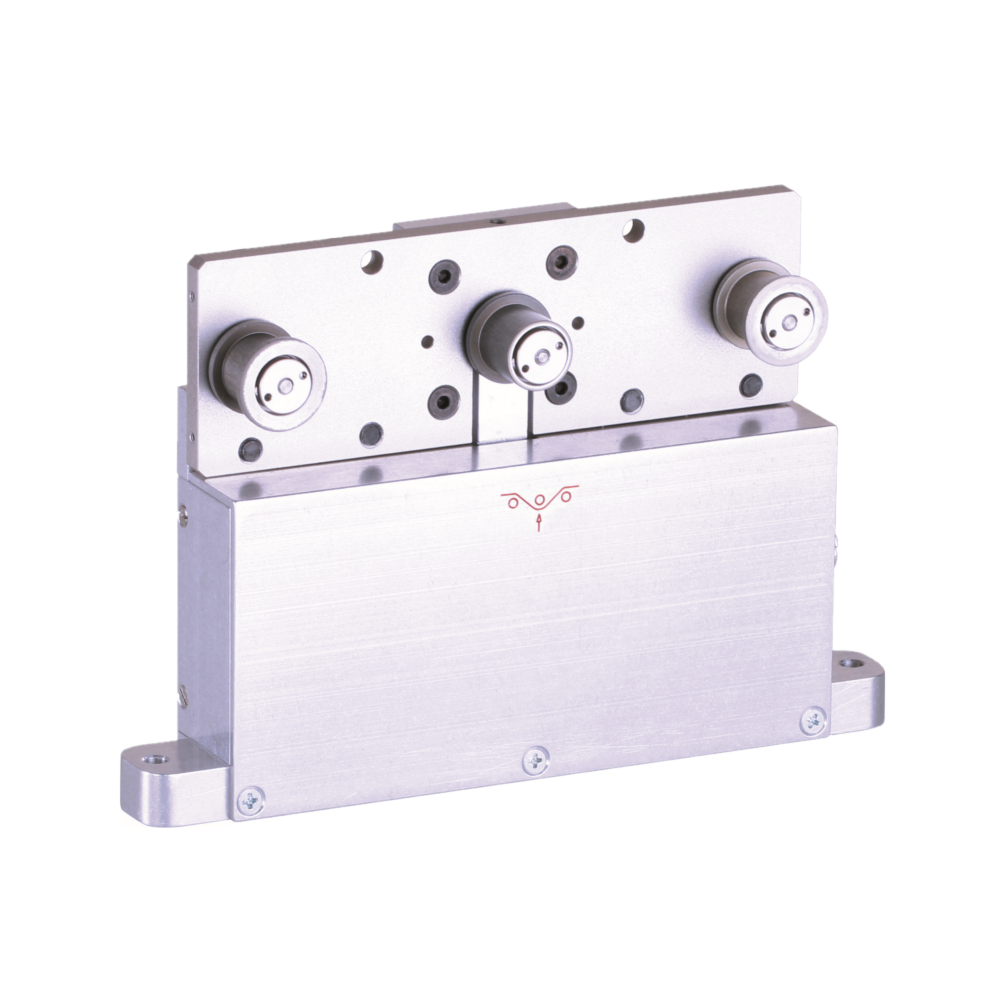

- Small, compact housing

- Tension sensor MZB1-422 with integrated microprocessor controlled measuring amplifier and RS-422 interface for multi station system

- Typical material path – warping the 3 rollers

- Various roller widths from 7 mm up to 20 mm according to the application are available. The roller width must correspond with the width of the material to be measured

- Easy installation, even afterwards, on existing machines

- Universal mounting possibility – easy to install, even afterwards, on existing machines:

The sensor can be mounted using the two threads at the underside of the housing body. Alternative it can be fixed on two flanges on the side of the unit. - Easy calibration to customized material by operator – zero and gain calibration is required

- Measuring principle – load cell with high quality strain gauge bridge

Standard Features

- Control lamp shows operative mode availability

- Tension sensor MZB1-422 with aluminium housing

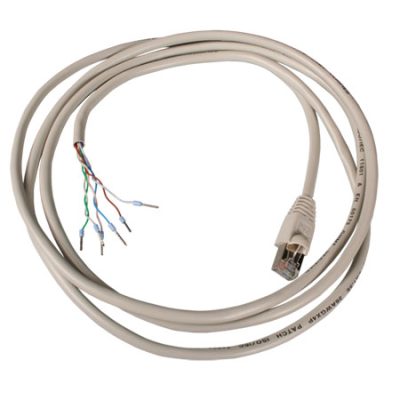

- CAT 5 cables are used for data transfer

- Required power supply +15…24 V DC (regulated)

- Certificate of Compliance with the order 2.1 according EN 10204 is included

- Optionally available: Inspection Certificate 3.1 according EN 10204 with calibration report

Special features of the RS-422 interface:

- Up to 24 sensors with different tension ranges and designs may be connected in one line (data transfer max. 200 readings/sec.)

- Connection to RS-232 using a converter (RS-422 – RS-232).

- The RS-422 signal can be used for a single sensor over a distance of 1000 m.

- Each sensor can individually be addressed and set up

- Can be connected to PLC controls with digital input

- Simple connection to BUS-Systems using gateways

Available Models

| Model | Tension Range* |

Measuring Head Width** |

Roller Width |

| MZB1-1000-422 | 0 – 1000 cN | 120 mm | 7, 10, 15, 20 mm |

| MZB1-2000-422 | 0 – 2000 cN | 120 mm | 7, 10, 15, 20 mm |

| MZB1-5000-422 | 0 – 5000 cN | 120 mm | 7, 10, 15, 20 mm |

| MZB1-10K-422 | 0 – 10 daN | 120 mm | 7, 10, 15, 20 mm |

Other tension ranges available on request.

Other measuring units available, such as g or kg

* SCHMIDT calibration material depending on tension range and roller width

** Outside dimensions of front plate

Important for your order:

Please specify model and roller width! Small dual-flanged outer guide rollers are standard. All 3 rollers can be equipped with one flange, if the material to be measured is wider than the rollers. Please request when you order.

Calibration to customized material:

If process material differs significantly from the SCHMIDT calibration material in diameter, rigidity or shape, special calibration using customer supplied samples is recommended. For this purpose a material sample of about 5 m should be supplied.

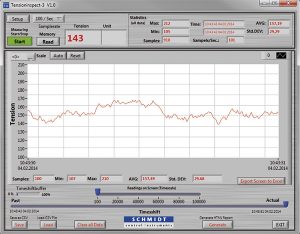

For displaying and saving readings on a PC (Win 7 and higher; 32 Bit und 64 Bit).

For displaying and saving readings on a PC (Win 7 and higher; 32 Bit und 64 Bit). Converter from RS-422 to RS-232 with terminal strip.

Converter from RS-422 to RS-232 with terminal strip. Cat 5 cable with open ends for RS-422/RS-232 converter and power supply to connect the last sensor. Length 3 m.

Cat 5 cable with open ends for RS-422/RS-232 converter and power supply to connect the last sensor. Length 3 m. Cat 5 cable for series connection of the sensors, length 3 m.

Cat 5 cable for series connection of the sensors, length 3 m. Connecting cable for connecting EBG-800 converter to PC, length 2 m.

Connecting cable for connecting EBG-800 converter to PC, length 2 m. Recharger with 4 adapters (EU/USA/UK/AUS-NZL) for worldwide use,

Recharger with 4 adapters (EU/USA/UK/AUS-NZL) for worldwide use,