Special Features

- Tension sensor TSW with integrated measuring amplifier

- Guide rollers 60 mm groove Ø, V-grooved or U-grooved, ball-bearing mounted

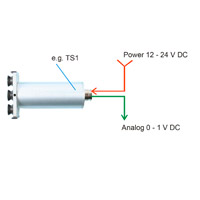

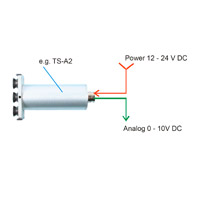

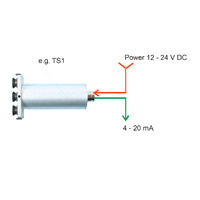

- Various output signals are available:

– analog: 0 – 1 V DC (standard), 0 – 10 V DC (optional)

– current: 4 – 20 mA (optional)

– analog DMS: mV/V (optional) - Easy installation, even afterwards, on existing machines

- Different guide rollers are available, according to the application

- Easy calibration to customized material by operator – zero and gain calibration is required

- Measuring principle – load cell with high quality strain gauge bridge

- Tension sensor TSW with mechanical overload protection

Note: a wide range of custom designed models as well modifications are available on request. Please contact us with your demand!

Standard Features

- Tension sensor TSW with rugged aluminum housing

- Required power supply +15…24 V DC (regulated)

- Certificate of Compliance with the order 2.1 according EN 10204 is included

- Optionally available: Inspection Certificate 3.1 according EN 10204 with calibration report

Available Models

| Model | Tension Range |

Measuring Heas Width* |

SCHMIDT Calibration Material** |

| TSW-20K | 0 – 20 daN | 550 mm | steel rope 1.50 mm Ø (7x7x0.20) |

| TSW-50K | 0 – 50 daN | 550 mm | steel rope 3 mm Ø (6x7x0.30) |

| TSW-100K | 0 – 100 daN | 550 mm | steel rope 4 mm Ø (6x7x0.50) |

Other tension ranges available on request.

Other measuring units available, such as kg.

* Outside dimensions of front plate

Calibration to customized material:

If process material differs significantly from the SCHMIDT calibration material in diameter, rigidity or shape, special calibration using customer supplied samples is recommended. For this purpose a material sample of about 5 m should be supplied.

Diode plug suitable for sensors of TS series,

Diode plug suitable for sensors of TS series, Connecting cable with 2 diode plugs, for analog output and voltage signal.

Connecting cable with 2 diode plugs, for analog output and voltage signal. Connecting cable with 1 diode plug and open ends, for analog output and current signal.

Connecting cable with 1 diode plug and open ends, for analog output and current signal.